what size combustion chambers do i need to make a 40 over 350 get 10.1 compression ratio

Is there a cheap way to increase pinch on my small cake Chevy? I take a 350 small-scale block with iron heads. I don't know much about the engine because it came in the car. The previous possessor said it was rebuilt and has a cam but he couldn't remember the specs. The other parts are an Edelbrock Performer intake, a 600 cfm Holley carb, and bandage iron exhaust manifolds. The engine runs fine on the cheap 87-octane stuff and doesn't ping at all. I'm thinking a trivial extra compression wouldn't' hurt but I tin can't afford a set up of aluminum heads. What practice you retrieve? Cheers

J.H.

Jeff Smith: Raising the compression ratio is an splendid idea for several reasons. Bold that the added compression is not excessive, adding compression is the best way to better power while also improving efficiency. There's a reason that all the latest generation LS engines and especially the new gasoline direct injection (GDI) LT1 Corvette engine have higher compression ratios. The LT1 is designed to operate with premium fuel but comes from the factory with a truthful 11:1 static pinch ratio.

Having said that, you tin't run that much compression on a small block Chevy using older, '70s vintage fe heads. Nosotros won't get into all the details as to why but suffice to say that those older combustion chambers were non designed to adapt that kind of compression. Internal combustion engineering has come a long way to accomplish these college static pinch ratios and still operate on 91-93 octane fuel.

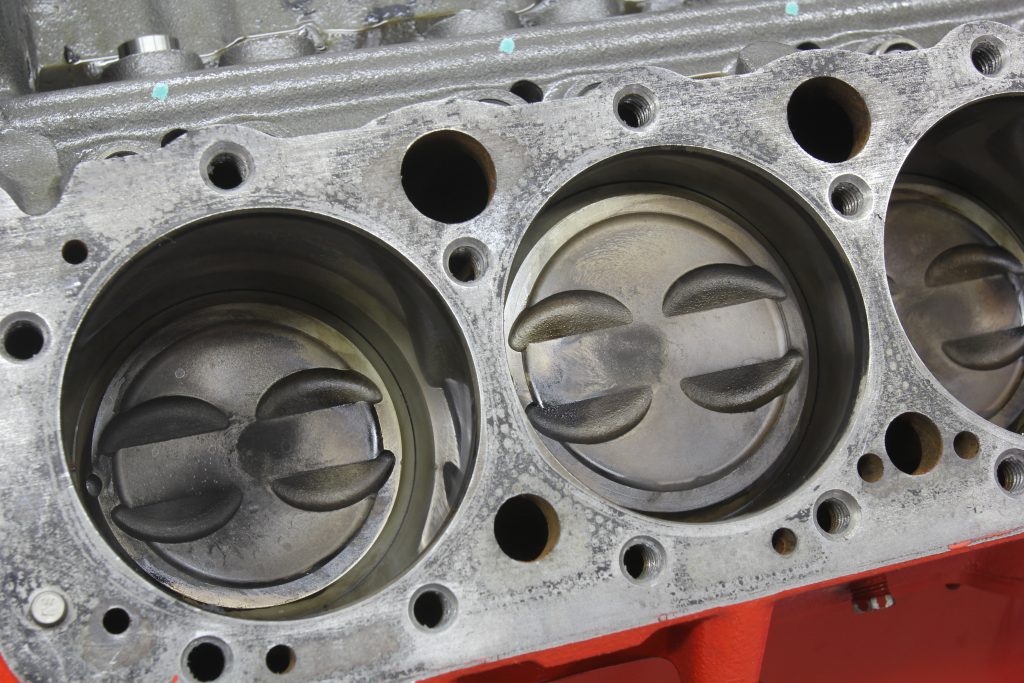

Since we don't know much about your 350 pocket-size block, nosotros'll assume it employs the typical apartment top, four eyebrow production pistons. With a limerick head gasket, the piston 0.020-inch below deck, and a 76cc combustion sleeping room, and with a limerick caput gasket this puts the static pinch at 8.5:1. This actually isn't bad. The standard Chevy 290-horsepower 350 Chevy crate engine you lot tin buy isn't even that proficient. Chevy's literature states this is an eight:1 compression engine, and that'due south what we found when we measured i of these engines a couple of years agone. This engine uses a dished piston with xiii cc's of volume that reduces the compression.

1 of the dimensions that is not easily inverse is the altitude from the piston top to the deck. In my compression ratio equation, I assumed the piston is 0.020-inch below the block deck surface, which is excessive, merely we tin can utilise that to our reward. If the pistons are closer to the deck (0.005-inch beneath for example), this improves the compression ratio simply besides limits the thickness of the head gasket since we are limited to roughly 0.040-inch for piston-to-caput clearance. With a 0.020-inch negative deck height, this means we tin use a thinner head gasket to amend the pinch.

Of course, this ways removing the cylinder heads to make this improvement and that's where many guys don't desire to make the endeavour. Here'southward how it works. Nosotros'll assume that your engine is currently using a composition head gasket. These are quality head gaskets but are generally 0.041-inch thick. Adding the 0.020-inch deck height to the 0.041-inch head gasket creates a distance of 0.061-inch between the elevation of the piston and the apartment portion of the cylinder caput. This is called the quench area.

It's interesting that many enthusiasts tend to overlook the combustion infinite equally a identify to improve engine power. The quench area is that flat portion of the piston that matches the flat portion of the combustion sleeping accommodation on a wedge type cylinder head.

When the piston achieves top dead centre (TDC), this creates a very tight clearance between the apartment portion of the piston and the flat portion of the head. This expanse is called the quench space or sometimes called squish–which is a really adept descriptor of its purpose. The quench area is designed to squeeze the trapped air and fuel in this area and squish it into the combustion chamber, creating turbulence. The key to quality combustion is to mix the air and fuel – or homogenize information technology. The quench expanse helps this process which tends to stabilize the speed of combustion once the spark plug lights.

The tighter you tin get this quench area–or the piston-to-head clearance–the better the engine volition run. Moving the piston closer to the deck surface also increases the static compression ratio. There is too a limit to piston-to-head clearance. By and large, for a low rpm street engine, y'all could be safe at 0.040-inch or slightly tighter. Loftier rpm race engines with steel rods will fit into the same clearance but aluminum rod engines must use more clearance (possibly around 0.050-inch) to accommodate the growth of the aluminum rods.

This photo shows checking the piston-to-deck clearance with a dial indicator. This is important data for blueprinting an engine and for accurately calculating the static compression ratio. It's also critical for knowing the piston-to-head clearance.

Since it will not exist feasible to disassemble your engine and deck the block, there's an alternative thought. Fel-Pro makes a steel shim head gasket with a very sparse rubber coating for a four.00-inch diameter 350 that is only 0.015-inch thick. When added to your 0.020-inch deck height, this produces a 0.035-inch piston-to-head clearance. This is a little tight but should be fine for a mild street engine that does not see engine speeds beyond half dozen,500 rpm.

The skillful news is that this gasket volition crash-land the static compression ratio up to eight.97:1 or substantially nine:1, which is worth roughly a one-half a point in pinch. A rule of thumb for engine is that a full bespeak of compression is worth roughly 3 to 4 per centum of engine ability. Bold 300 horsepower on your engine, a half-point of pinch is probably worth most 2 percent – which is but 6 horsepower. That sounds like a lot of piece of work for a minimal comeback, simply my guess is that low-speed torque will as well improve at least this much if not maybe a chip more.

Here is a photo of a 290-horsepower small block with dished pistons. If your engine has these pistons, look the pinch to be effectually 8.0:1 which is at least 1.five ratios away from where it needs to be. The easiest way to ameliorate pinch is with a prepare of 64cc chamber cylinder fe Vortec heads and that 0.015 head gasket, which will push the pinch up to 9.0:1

One farther recommendation would exist to add a set of mid-length headers to the engine. This will do more to add power than any other thing yous can do. Adding headers on a 290-horsepower small block was worth 30 ft.-lbs. of torque and 30 horsepower to that otherwise stock engine. My proffer would be to do both the head gasket and the headers and so you will definitely need to re-jet the carburetor slightly richer unless it was excessively rich to begin with–which is also possible.

Source: https://www.onallcylinders.com/2017/03/24/how-to-increase-compression-on-the-cheap/

0 Response to "what size combustion chambers do i need to make a 40 over 350 get 10.1 compression ratio"

Post a Comment